Working Principle

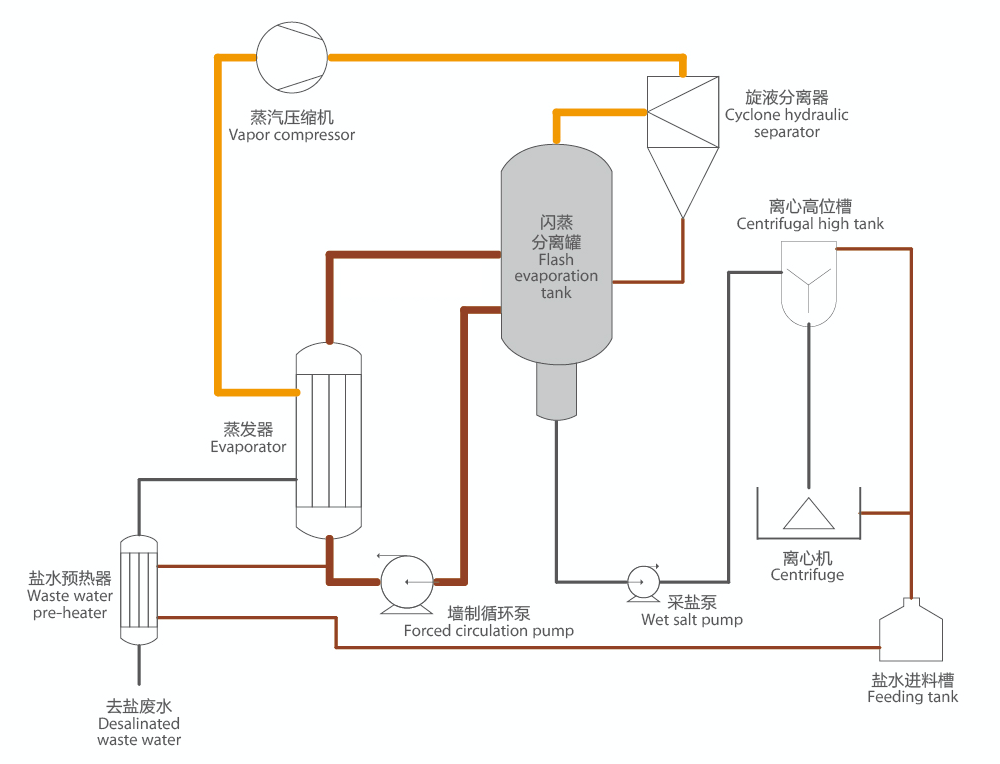

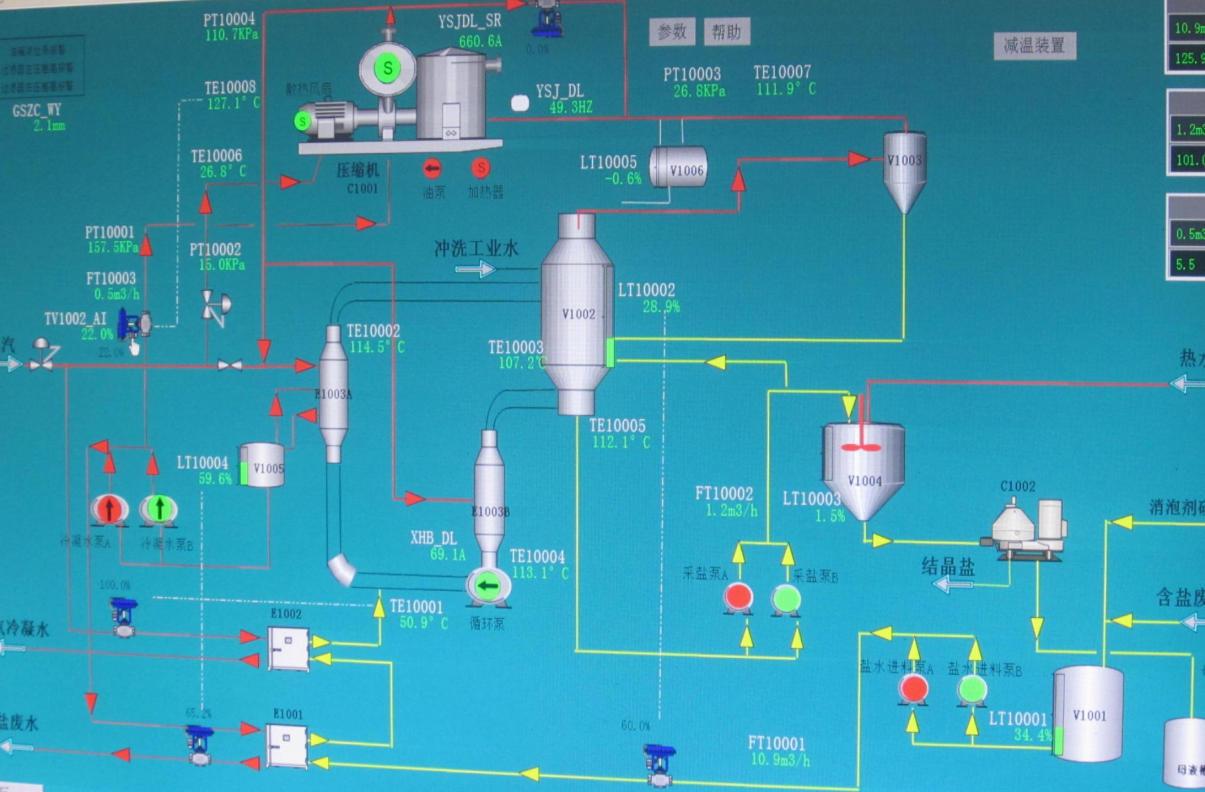

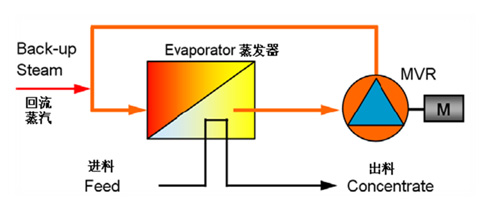

Mechanical vapor recompression (MVR) .The secondary steam generated by itself is compressed and heated by a compressor to increase its enthral, and its latent heat is fully utilized as a heat source to heat the feed liquid in the evaporator of the system again, so as to realize concentration, desalination and COD removal. Except that the system needs to be heated and preheated in the start up stage, other auxiliary heating is basically not needed or rarely needed in the operation process; the condensed water generated after the secondary steam is heat transferred.

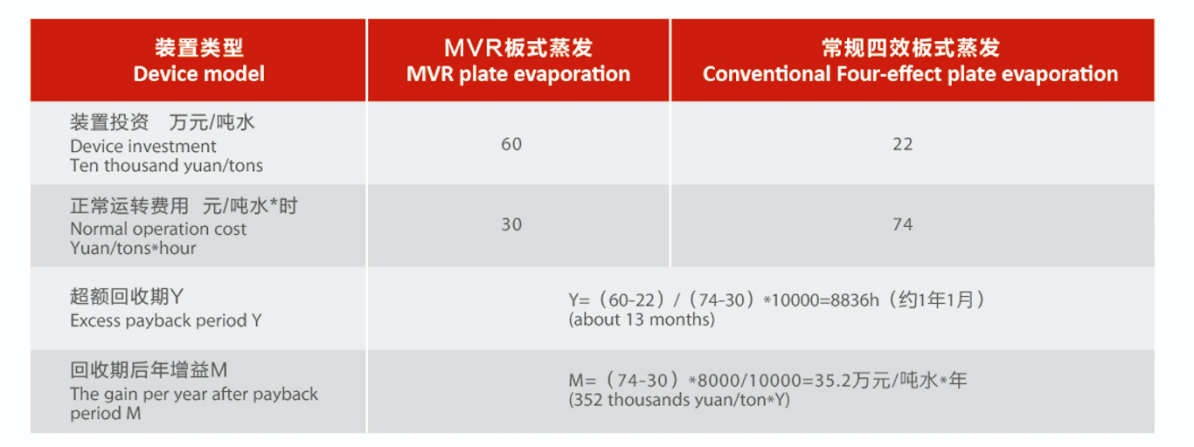

We devoted provide best solution of MVR evaporation with low operating costs and high economic efficiency.The process of MVR is compressing low temperature vapor by compressor, enhancing pressure and temperature and then increase heat function of vapor. Except for start-up, no fresh vapor is required during whole evaporation process. The secondary vapor, in increased heat function by MVR, will be sent to heating chamber of evaporator to heat material of process. After heating process, vapor becomes to condensate. In this program, secondary vapor is reused to save operation cost.

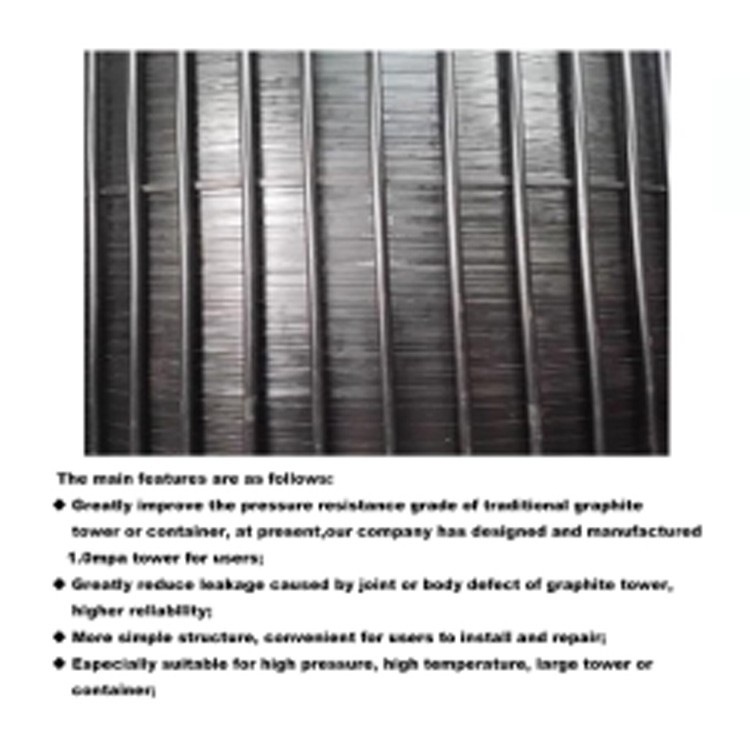

Graphite evaporator could replace traditional evaporation equipment because of excellent corrosion characteristics of graphite material, also using graphite evaporators can reduce equipment investment, improve heat transfer efficiency and prolong equipment service life.

MVR technology greatly contributes to both economic and social sections, that zero fresh vapor input during operation will save fuel consumption and reduce carbon emission as will,that less circulation cooling water required will also reduce air pollution.