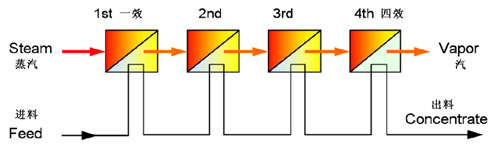

Multi-effect evaporation is a traditional energy-saving evaporation technology, which reduces the energy consumption of the system by using the per-heating energy. Steam is mainly energy consumption of the multi-effect evaporation, especially suitable for the operation environment where steam is sufficient and power is short. It is widely used in the evaporation, concentration, crystallization and waste water treatment of many industries such as medicine, food, chemical industry, printing and dyeing, etc.

Titanium dioxide waste acid treatment system

Application background:

The general titanium dioxide output capacity could reach 3.5 million tons, most of which are mainly manufactured in terms of sulfuric acid method titanium dioxide. Plenty of waste acid and waste water are generated during the sulfuric acid method production, if adopt the neutralization method there will be bulk waste plaster precipitated and contaminating the environment.

Treatment:

We offer two proposals for the treatment:

Proposal 1, through the simple low temperature evaporation and concentration method to improve the sulfuric acid consistence.

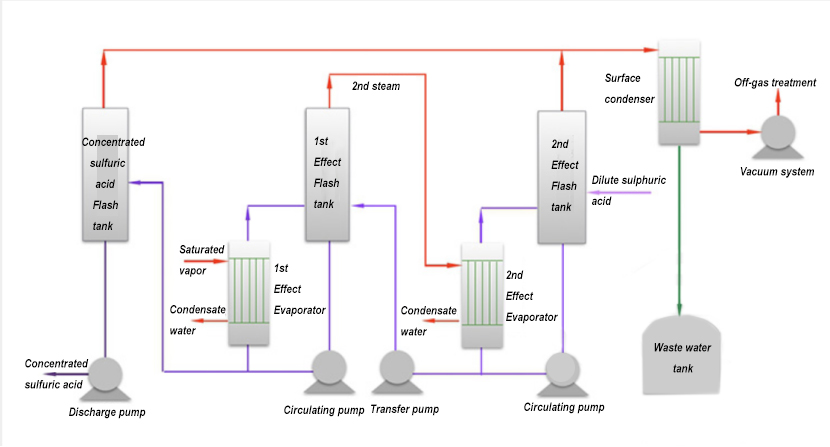

It adopts dual-effect counterflow and forced circulation plus flashing evaporation process through an adequately utilization of secondary steam to reduce the steam consumption, which is quite suitable for titanium dioxide waste acid treatment.

We choose complete graphite flashing separation tank with working life over 10 years.

Graphite axial waterjet pump is applied in forced circulation mode which saved the cost and improved working life.

The graphite evaporator has improved its heat transfer efficiency and decreased the pressure drop after optimized design.

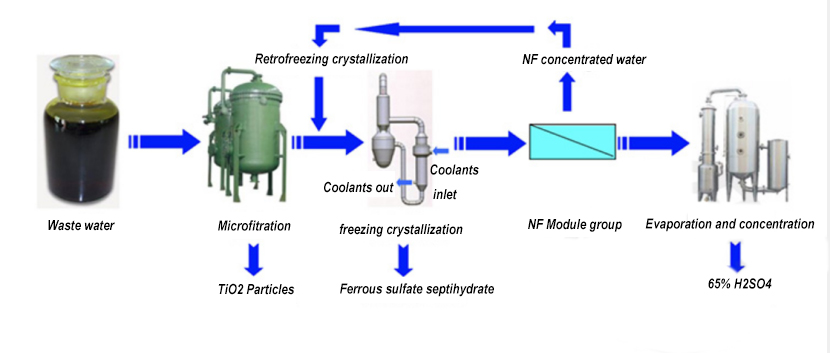

Proposal 2, separate the TIO2 and sulfate from the diluted sulfuric acid through membrane treatment device, then the purified diluted sulfuric acid flows into evaporation system for concentration, which has solved the phenomenon that the evaporator tends to be blocked easily.

Micro filtration is used for TIO2 solids recovery in the waste acid.

The ferrous sulfate is separated through chilling and crystallization.

The ferric ions is concentrated and removed with NF.

Application background:

The Sulfuric acid is usually applied as a raw material in metallurgy, titanium dioxide and other fields to attain a lower concentrated sulfuric acid, further more to acquire a desired consistence of sulfuric acid through the evaporation and concentration system.

Technical description:

Different evaporation modes are applied according to different material concentration and its impurities. The regular evaporation modes are classified into single-effect evaporation and multiple-effect evaporation, while the multiple-effect evaporation further more divided into cocurrent flow and counter flow. They’re classified into falling film evaporation, rising film evaporator or forced circulation evaporation by category, equipped with blow-off processing further more to improve the sulfuric acid concentration or remove the fluorine and chlorine from the sulfuric acid.

The diluted sulfuric acid concentration could reach 60%-95% through graphite evaporation system, which can be further more improved by tantalum evaporator.

The forced circulation is suitable for evaporation and concentration of the mediums which are easy in fouling and crystallizing, with high concentration, high viscosity and mediums containing granules. The medium flowing speed is accelerated under forced circulation to avoid fouling on the internal wall leading to a bad heat transfer effect.

Block hole type graphite evaporator or tubular graphite evaporator could be selected according to the mediums characteristics.

Graphite axial waterjet pump or PTFE waterjet pump could be applied according to the mediums characteristics of the forced circulation pump.

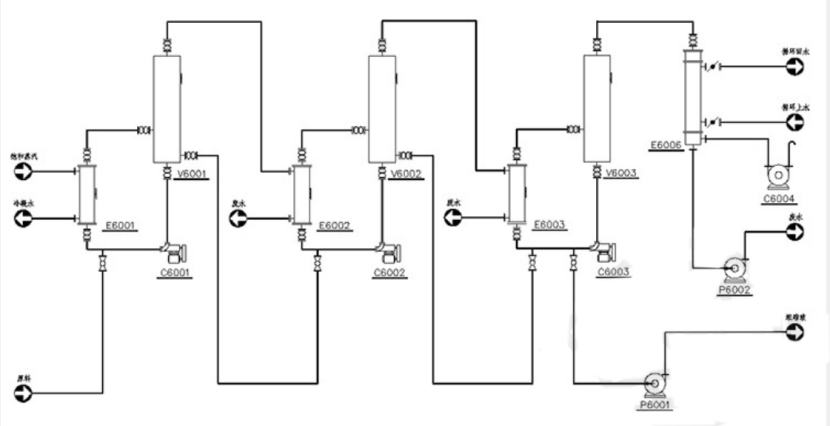

Triple-effect concurrent forced circulation evaporation process:

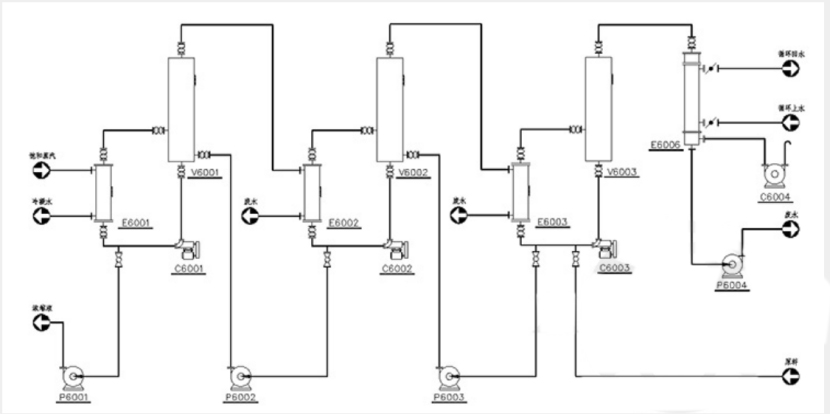

Triple-effect counter flow forced circulation evaporation process:

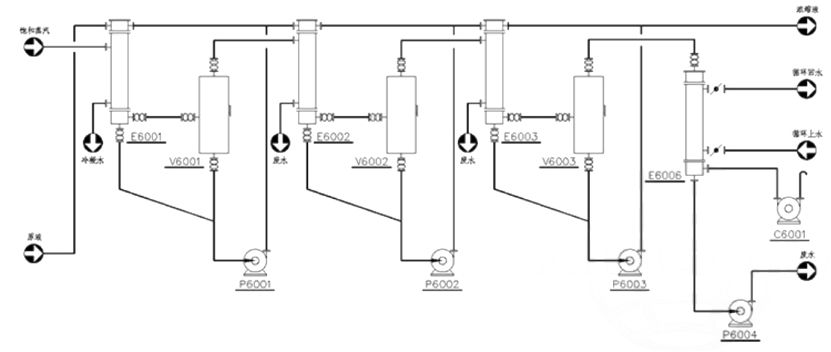

Triple-effect concurrent falling film evaporation circulation system:

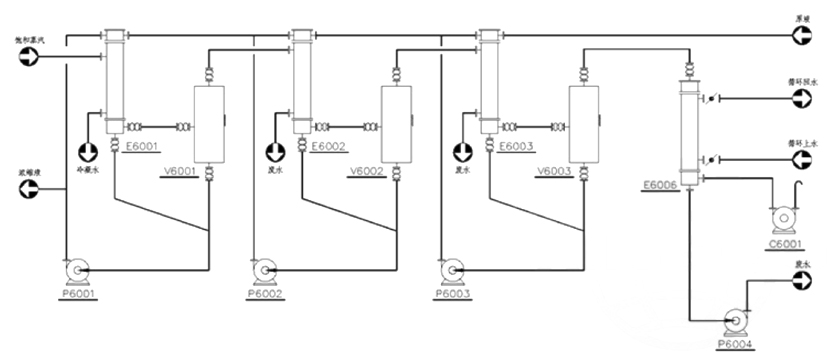

Triple-effect counter flow falling film evaporation circulation system:

Sulfuric acid concentration system in Jinchuan, Gansu Province.

HCL acid contained concentration and separation system in China PINGMEI COAL GROUP