Range of Application

The tubular graphite falling film absorber / Evaporator has a larger flow rate and a smaller flow resistance compared with the cylindrical block hole type graphite heat exchanger, which is suitable for larger graphite heat transfer surfaces application.

It’s mainly used in falling film evaporation system, with excellent distributing film and heat transfer effects. As it could be made into single larger unit which is especially adequate in large-scale evaporation system, while its shell side is with anticorrosive treatment and secondary steam endurable capacity

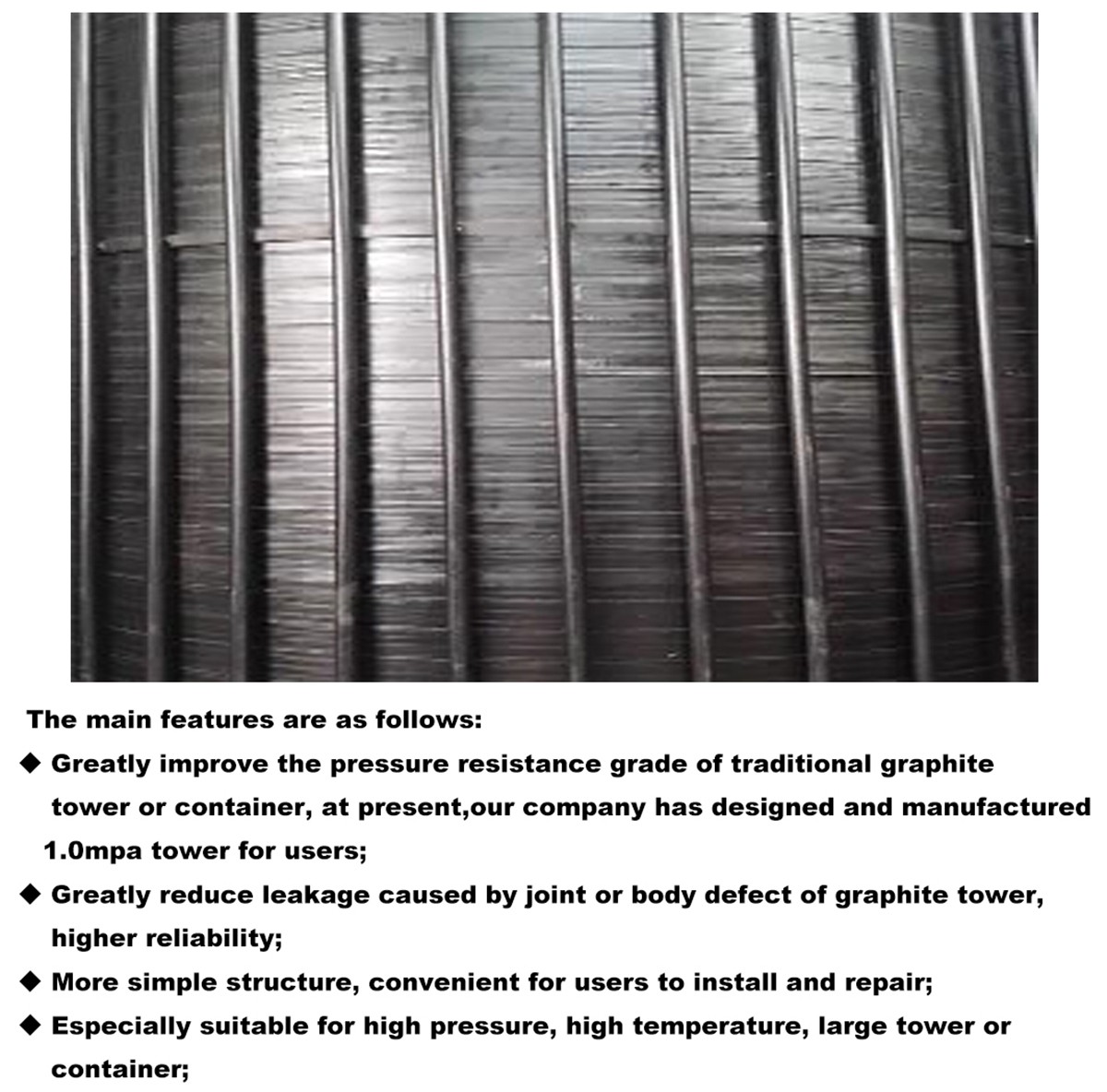

We adopt the single tube sealing which could eliminate stress caused by thermal expansion, and each tube is independently extracted and replaced for future maintenance.

Performance features

* Corrosive mediums could be applied in both process side and service side

* Full negative pressure could be applied in both process side and service side

* High efficiency in heat transfer

* Small fluids resistance and fouling resistance

* Single tube is replaceable and easy for maintenance

* Larger heat transfer area is available

* Lower cost advantage than block hole type heat exchanger

* Abrasion resistance treatment is available

Technical Characteristic

Name | Process side | Service side |

Design pressure | 1.0MPa | 1.0MPa |

Design Temp. | 180℃ | 180℃ |

Medium | Corrosive medium | Water, steam, and corrosive medium |

Heat exchange area | 2 ~1000m2 |

Bore diameter | φ50/φ36, φ37/φ25, φ32/φ22 |